[Courtesy of KIMM]

Defect detection has been used to save costs and inspection time. AI computer vision-based cameras continuously photograph products and compare them with the images of non-defect products. The global market for computer vision is forecast to hit $19.1 billion by 2027, according to global market research firm Grand View Research.

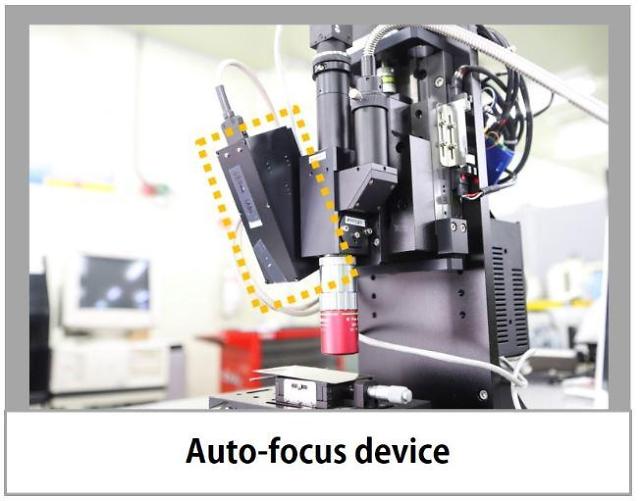

Auto-focusing equipment helps AI-based inspection microscope lenses to quickly focus on the surface of various materials and get clear images. Many South Korean factories use imported auto-focusing equipment.

The Korea Institute of Machinery & Materials (KIMM), a state-funded research institute, said in a statement on June 3 that its research team has developed an auto-focusing device for the defect inspection of large-sized display panels. The new equipment using a laser semicircular masking displacement technique can rapidly and precisely focus on panels.

"Auto-focusing equipment for microscopes and laser processors is widely used in the display industry, a key business area of major South Korean companies, but so far the field has relied heavily on imports," KIMM researcher Noh Ji-whan was quoted as saying. "Our study will significantly enhance the competitiveness of local businesses."