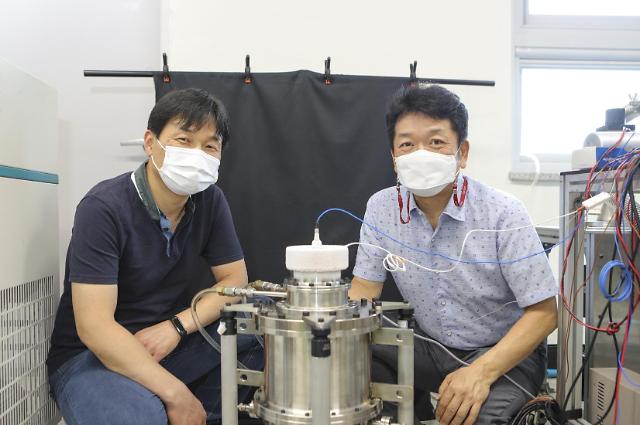

[Yonhap Photo]

Infrared sensors, also known as thermopiles, measure temperature from a distance by detecting the infrared energy generated by objects. Higher the temperature of the object, the more infrared energy is emitted.

The Ministry of Science and ICT said in a statement that the state-run National Nanofab Center, a state-funded nanotechnology institute, and Tempus have jointly developed the thermopile sensor using a simplified microfabrication process and the complementary metal-oxide-semiconductor to ensure stable production and reduce manufacturing costs.

The sensor is up to five times more sensitive than other thermopiles manufactured by American and German companies which have dominated the global thermopile market, the ministry said. "We will aggressively target non-contact thermometer markets at home and in other countries as we are capable of mass-producing the new infrared sensor and expand its application," Tempus CEO Shin Baek-kyu was quoted as saying.

According to Research and Markets, a market research firm, the global market for non-contact thermometers will grow at an annual average growth rate of 15 percent to reach $73.59 million by 2025. The demand for non-contact thermometers has skyrocketed this year due to the COVID-19 pandemic because it does not require physical contact.