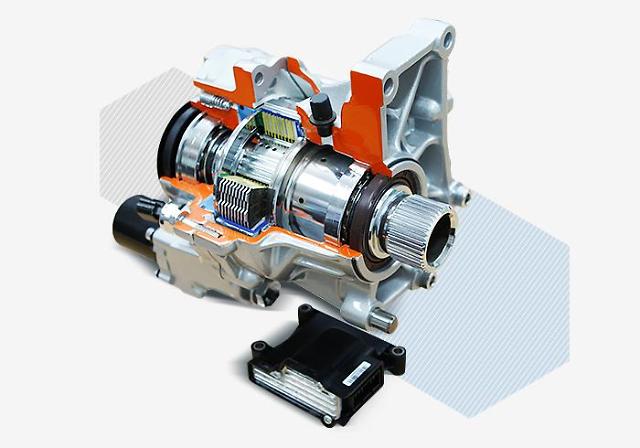

[Courtesy of Hyundai Wia]

SEOUL -- Hyundai Wia, a parts-making unit of South Korea's Hyundai auto group, will commercialize an integrated smart solution based on cooperative robots and autonomous driving for cellular manufacturing. The manufacturing process will be done in a cell where machine tools and robots work together to increase the speed of assembly and processing.

Hyundai Wia said that its RnA (robotics and autonomy) integrated solution would convert conveyor belt-type manufacturing sites into a cell, which is used in the cellular manufacturing concept for the efficient flow of materials, placing machines and supplies in one strategic location. Cell manufacturing can eliminate overproduction waste, excess inventories and over-processing inefficiencies.

The RnA-based solution will be applied to the Hyundai auto group's innovation center, which is under construction in Singapore for future mobility research and development. Afterward, Hyundai Wia aims to expand the supply of its solution to manufacturing sites abroad.

Hyundai Wia said in a statement on November 19 that the company would develop algorithms that link cooperative robots, self-driving logistics robots and machine tools while applying "bin picking" robot technology using three-dimensional vision recognition. Bin picking is a core problem in computer vision and robotics.

A smart logistics and robot control system would be planted to optimize production by collecting processing and assembly information in a cell in real-time and controlling the supply of parts and raw materials, Hyundai Wia said, adding that machine tools would be optimized for integrated solutions based on robot self-driving, and users can check the status of all machines anytime and anywhere using smartphones.