[Courtesy of KIST]

SEOUL -- South Korean researchers developed a low-carbon, highly efficient photocatalyst-based peroxide production technique that does not need expensive metals such as palladium. The researchers were able to achieve an unprecedented concentration of peroxide using the photocatalyst-based method.

Peroxide, the core chemical material used for the production of various important products such as semiconductors, disinfectants, and pulp, is mainly generated through a complex thermochemical process involving expensive palladium catalysts in a high-pressure and high-heat environment. It is an energy-consuming process with low efficiency with a lot of carbon emission. The production process for peroxide also generates chemical pollution that could harm the environment.

The global peroxide market, estimated to reach some seven trillion won ($5.5 billion) in 2024, is experiencing a supply shortage due to the prolonged coronavirus pandemic and explosive demand increase in the global semiconductor market.

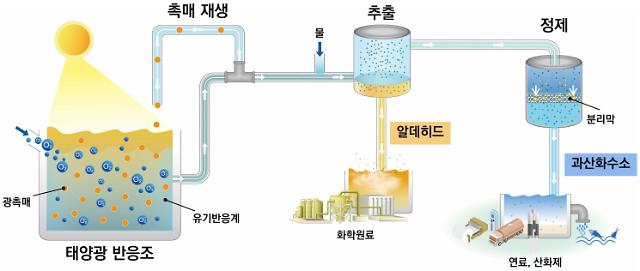

The Korea Institute of Science and Technology (KIST) said that its research team found a new effective peroxide production technique by replacing the conventional thermochemical process with a photocatalytic process that uses an organic solution as a photocatalytic reaction media. For the first time, the researchers were also able to prove that the organic solution absorbed light to trigger a photochemical reaction to create peroxide.

KIST said that through tests, the research team was able to achieve the concentration rate of 53,000 ppm (5.3 percent concentration rate) per gram of a photocatalyst. The concentration rate was about five times higher than the concentration rate of commercial peroxide production systems. The solar-to-chemical conversion efficiency of the photocatalyst reached 1.1 percent, up about 0.5 percent point from the highest-ever recorded efficiency rate of 0.61 percent.

"This research is a good example that shows low-carbon solar energy-based technology can also produce a core industrial material with a high concentration rate and high purity," KIST said in a statement on December 28.